Fatigue Meter called attention to a driver with chronic elevated fatigue and a history of frequent safety critical events. After the fleet manager initiated a coaching conversation, the driver’s safety record improved dramatically.

Challenges

Improve collaboration between fleet managers and drivers to mitigate fatigue causal factors.

Educate drivers about the benefits of finding the right mitigation strategies that work for them.

Strengthen team dynamics to help drivers create positive behavioral change.

Products and services

“This is a great example of how collaborating with drivers to manage fatigue can go a long way toward creating a safe and productive work environment. Drivers are critical to the success of the operation, and it’s just good business to help them be healthy and fit for duty.”

Daniel Mollicone, CEO, Pulsar Informatics

Fatigue Meter called attention to a driver with chronic elevated fatigue and a history of frequent safety critical events. After the fleet manager initiated a coaching conversation, the driver’s safety record improved dramatically.

Solution

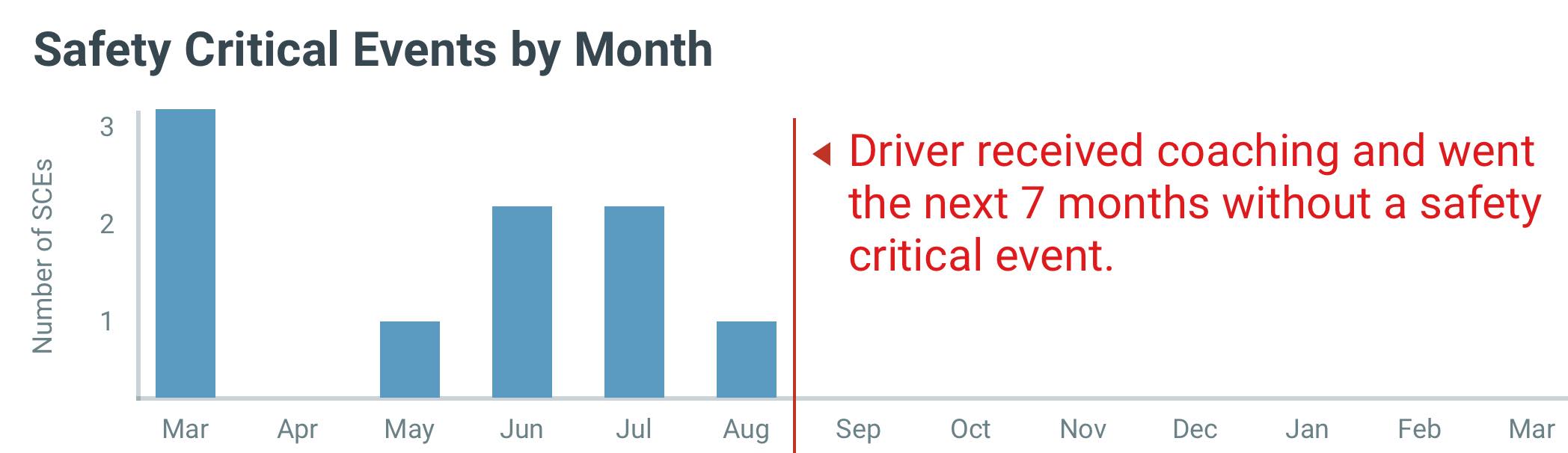

After the driver’s third roll stability event in two weeks, his fleet manager called him to check in. The driver explained that the events were caused by deer jumping into the road, but as they were talking the fleet manager opened the driver’s profile in Fatigue Meter and saw his fatigue was at peak levels during each event. He asked the driver if he was getting enough rest. The driver answered that he felt fine and that he was getting enough sleep. The fleet manager suggested he come in to discuss in person.

The next day, the fleet manager started by saying that he believes fatigue contributed to the recent safety critical events. He showed the driver his Fatigue Meter profile and explained how the system estimates sleep periods and predicts fatigue based on hours of service. The driver was clearly hesitant to discuss his sleep schedule, so the fleet manager simply asked him to be mindful of how much sleep he gets and to work on improving his safety critical event count.

A few weeks went by and the driver’s safety record was clean. In a follow up conversation, the driver denied making changes in his work/rest habits; however his Fatigue Meter profile showed three considerable behavior changes. First, he began to use his sleeper berth for about one hour during night shifts. Second, instead of working to the HOS duty hour limit every day in order to get home after work, he slept every other night in his sleeper berth. Lastly, he stopped his truck for 10 minutes every few hours, presumably to get out and stretch before continuing on. Seven months went by, during which time the driver did not experience a single new safety critical event.

This driver’s story shows that coaching backed up by data drives real change. When aggregated over an entire fleet, it can have a big impact on safety.