J. B. Hunt Intermodal in Harrisburg continues to see positive ROI from their safety initiatives with a further year-over-year improvement in safety indicators and reduced operational costs. Fatigue MeterTM is a core part of the driver coaching and intervention process that enables the carrier to achieve its safety and productivity targets.

Challenges

Enhance the driver coaching and intervention process to reduce fatigue risk.

Continue to refine fatigue risk management procedures to reduce fatigue-related accidents and incidents.

Provide drivers with 24/7 dispatch and managerial support to help address fatigue risk and other safety issues during the night shift.

Products and services

"After our fleet managers started regularly monitoring our systems every two hours for possible fatigue related issues and other safety violations, we got ahead of the ball and were able to quickly identify and take care of issues that would normally take more time to clean up if discovered later.”

Tedd Pounds, Regional Safety Manager - Northeast

J. B. Hunt Intermodal in Harrisburg continues to see positive ROI from their safety initiatives with a further year-over-year improvement in safety indicators and reduced operational costs. Fatigue MeterTM is a core part of the driver coaching and intervention process that enables the carrier to achieve its safety and productivity targets.

Solution

Customer Goals

J. B. Hunt Intermodal began using Fatigue Meter in early 2016 to help manage driver fatigue risk. Recognizing that the success of any safety initiative relies on the combination of people, process, and technology, Regional Safety Manager Tedd Pounds worked with his team to enhance the driver intervention and coaching process.

Achieving People, Process, and Technology Synergy

Fleet managers were already responding to email alerts sent by Fatigue Meter whenever a driver reached an elevated fatigue risk status. When an alert came in, they would contact the driver to have a safety check-in and develop a plan for the remainder of the driver’s shift.

In 2018 fleet managers were asked to take a more proactive monitoring approach. At the start of each work shift, they reviewed the list of active drivers in Fatigue Meter to look for any current or imminent fatigue related issues. They also checked their dispatch system to identify any HOS violations.

“After our fleet managers started regularly monitoring our systems for possible fatigue related issues and other safety violations, we got ahead of the ball and were able to quickly identify and take care of issues that would normally take more time to clean up if discovered later,” said Tedd.

Extra steps were also taken during the winter months and days with inclement weather. “When road conditions are bad, I send a message to the fleet managers in my area and emphasize the stress that comes with driving in inclement weather. Driver fatigue combined with bad weather creates the perfect storm for serious safety issues,” said Chris Dazsi, Area Risk Manager Northeast. “I ask the fleet managers to consider lowering the fatigue threshold in Fatigue Meter to account for this extra risk, so that they can be alerted to potential issues sooner.”

Result

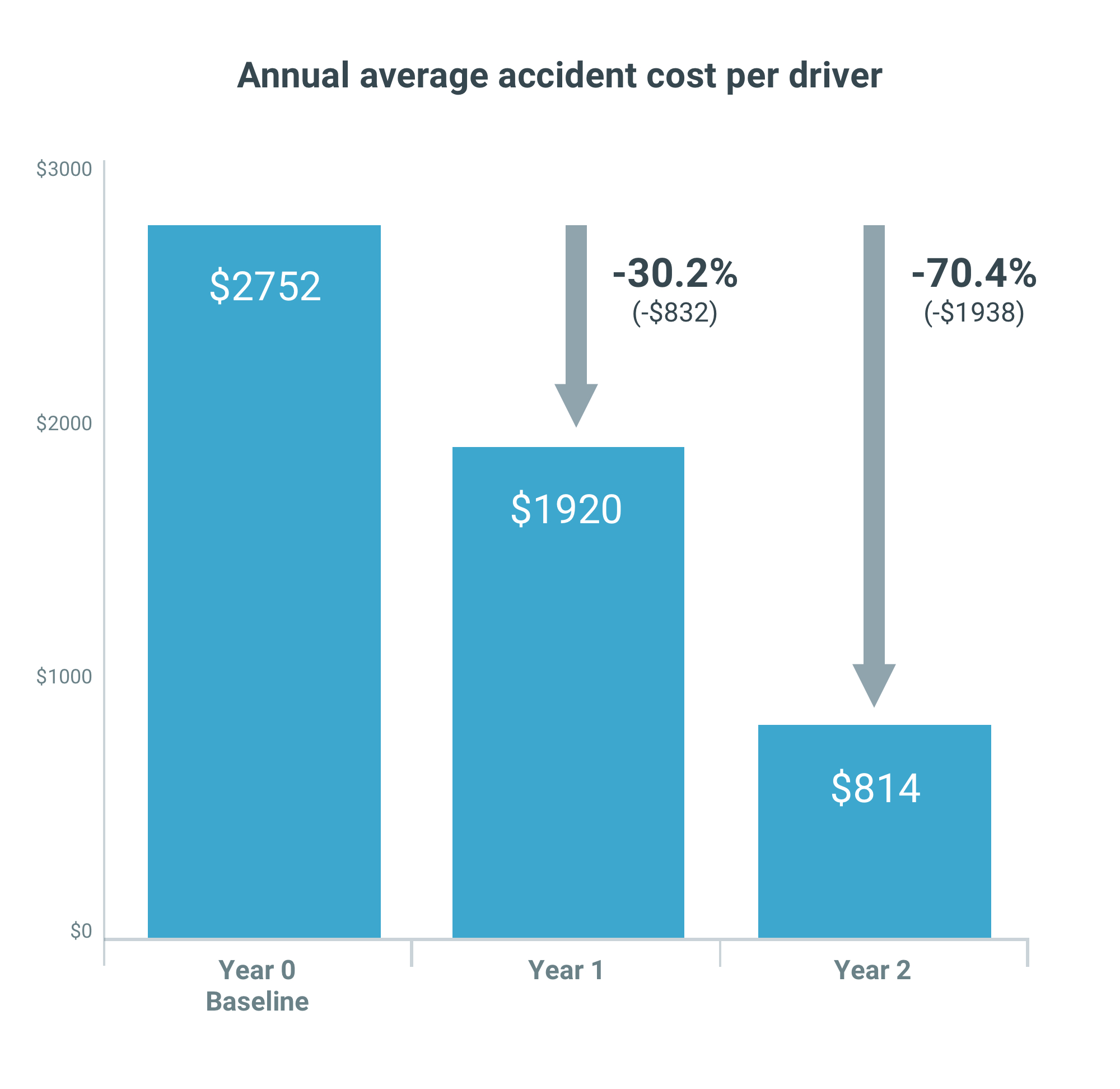

Fleet managers at the J. B. Hunt Intermodal terminal in Harrisburg have about 300 drivers enrolled in active monitoring and coaching. Accident costs per driver dropped 30% in the first year after implementing the program, and 70% in the second year – an annual average cost savings of $1,938 per driver. The total annual savings in accident related costs now exceeds $500,000.